- Home

- Poultry Shears

- Chicken Shears With PP+TPR Material Handle -Comfortable Grip

Chicken Shears Video

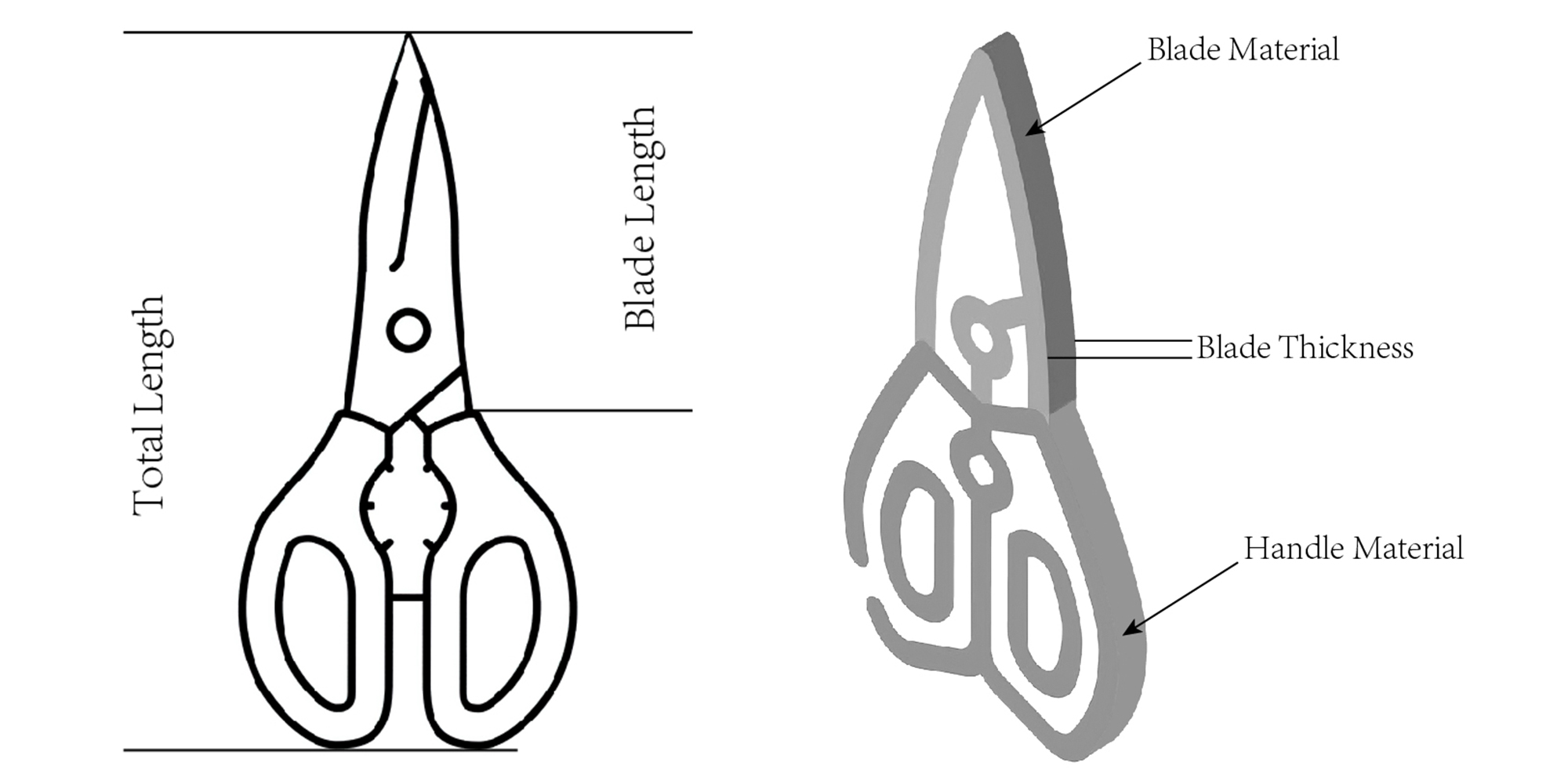

Name |

Specification |

|---|---|

Total Length | 247 mm / 9.7 In |

Blade Length | 167 mm / 6.5 In |

Blade Thickness | 3.5 mm / 0.138 In |

Blade Material | X30Cr13 or 420J2 |

Handle Material | PP(15%glass fiber) + TPR |

Weight | 192 g |

Materials such as X30Cr13 and 420J2 are commonly used for the manufacturing of chicken shears. Both of these steels fall under martensitic stainless steel, primarily utilized for blade production. The choice between them depends on specific usage requirements, such as hardness, corrosion resistance, and edge retention. Proper usage and maintenance are also key to ensuring prolonged Shears longevity.

X30Cr13:

Chemical Composition: X30Cr13 is a stainless steel with the following main components:

- 0.26% Carbon (C)

- 1.00% Silicon (Si)

- 1.00% Manganese (Mn)

- 13.00% Chromium (Cr)

Characteristics:

- Hardness: Typically exhibits high hardness, suitable for manufacturing knife blades.

- Corrosion Resistance: Possesses some corrosion resistance but relatively lower, requiring proper maintenance.

- Edge Retention: Shows good edge retention, maintaining sharpness for a relatively long time.

420J2:

Chemical Composition: 420J2 is also a stainless steel with the following main components:

- 0.26-0.40% Carbon (C)

- ≤1.00% Silicon (Si)

- ≤1.00% Manganese (Mn)

- 12.00-14.00% Chromium (Cr)

Characteristics:

- Hardness: Relatively hard, suitable for producing robust and durable knife blades.

- Corrosion Resistance: Exhibits good corrosion resistance, making it quite durable for general kitchen use.

- Edge Retention: 420J2 is relatively easy to sharpen and can maintain its edge for a considerable period.

The handle of chicken shears plays a pivotal role in determining the overall functionality and user experience of this essential kitchen tool. Its importance extends beyond mere aesthetics, encompassing crucial aspects that directly impact the effectiveness and safety of poultry preparation.

A High-Quality Chicken Shears Handle Must Meet the Following Five Basic Criteria.

- Comfortable grip

- Non-slip design

- Durability

- Easy to clean

- Well-balanced

When choosing chicken shears, pay special attention to the design and quality of the handle to ensure optimal performance in cooking and food preparation, providing a convenient and safe user experience.

Here is our compiled introduction to various materials to assist you in choosing the most suitable one. Of course! You can also contact us directly, and we would be delighted to answer all your questions about custom chicken shears.

Unique Advantages of ABS Material Chicken Shears Handles:

- Excellent Toughness:

ABS (Acrylonitrile Butadiene Styrene) material is known for its outstanding toughness, providing chicken shears with strong impact resistance. This makes the shears more durable and reliable when handling various ingredients.

- Sturdy and Durable:

The robust design of ABS handles imparts high wear resistance, withstanding prolonged and frequent use. This ensures excellent performance of the chicken shears, whether dealing with hard ingredients or extensive cooking.

- Temperature Stability:

ABS exhibits good temperature stability, maintaining its structure and performance under common cooking temperatures. This makes chicken shears with ABS handles a popular choice, especially in high-temperature kitchen environments.

- Diverse Design Possibilities:

ABS is easy to process and mold, allowing for a variety of designs. This versatility enables unique aesthetic designs for chicken shears handles based on individual preferences and design trends.

Distinctive Features of PP Material Chicken Shears Handles:

- Lightweight and Flexible:

The polypropylene (PP) material handle is lightweight and flexible, providing users with a comfortable grip. This makes chicken shears less likely to cause hand fatigue during extended use.

- Strong Chemical Resistance:

PP exhibits good chemical resistance, capable of withstanding contact with chemicals from food and cleaning agents. This convenience contributes to maintaining hygiene in chicken shears.

- Cost-Effective:

As a cost-effective material, PP strikes a good balance between performance and cost for chicken shears handles. This makes PP-handled shears an economically practical choice.

- Easy to Clean:

The smooth surface of PP is resistant to food residue adhesion, making it easy to clean. This feature ensures that chicken shears are easily maintained in a clean and sanitary condition after use.

PP +15% Glass Fiber + TPR, Utilizing PP (Polypropylene) Combined with 15% Glass Fiber Reinforcement and TPR (Thermoplastic Rubber), the Chicken Shears Handle Is Crafted with Multiple Advantages:

- Enhanced Strength and Rigidity:

The addition of 15% glass fiber reinforcement to PP significantly enhances the overall strength and rigidity of the handle. This makes the shears more robust and capable of withstanding greater mechanical stress.

- Improved Durability:

Glass fiber reinforcement enhances the durability of the PP material, making the handle more resistant to wear. This increases the lifespan of the shears.

- Reduced Weight:

Despite the addition of glass fiber reinforcement, incorporating glass fiber into PP helps maintain a relatively low weight. This is beneficial for users who prefer lighter shears, enhancing convenience and maneuverability.

- Excellent Grip and Comfort:

TPR (Thermoplastic Rubber), known for its soft rubbery texture, provides an excellent grip and enhances overall user comfort. Combining TPR with reinforced PP ensures an ergonomically comfortable design for the shears handle.

- Moisture Resistance and Chemical Resistance:

Even with added glass fiber reinforcement, PP typically retains its moisture resistance, and TPR is known for its water resistance. This combination makes the shears less susceptible to water-induced damage while maintaining resistance to common kitchen chemicals.

- Durable in High-Temperature Environments:

Reinforced PP can withstand higher temperatures, making the shears suitable for high-temperature environments such as cooking and cleaning.

- Long-Lasting Sharpness:

The enhanced strength and durability of the handle contribute to the overall lifespan of the shears, aiding in maintaining blade sharpness over an extended period.

- Diverse Design Options:

Manufacturing chicken shears handles with reinforced PP and TPR allows for a variety of design possibilities, providing manufacturers with aesthetically pleasing and highly functional shears.

Regardless of whether you choose ABS, PP, or PP+15% Glass Fiber+TPR materials for crafting the handle of chicken shears, each material brings unique advantages, turning your chicken shears into a practical and stylish culinary tool. Furthermore, the combination of PP with glass fiber reinforcement and TPR is designed to optimize the handle’s strength, durability, and user comfort.

However, it’s important to note that the specific performance of chicken shears depends not only on the materials used but also on the product’s design, structure, and overall quality. Therefore, when making a choice, consider not only the advantages of the materials but also the comprehensive performance of the product to ensure an exceptional cooking experience that meets your expectations.

We have abundant raw material inventory and strict storage standards to ensure zero errors and meet your diverse needs, all while ensuring the timeliness of production.

At our factory, we create scissors to order, meaning that we don’t have a set minimum order quantity that applies to all products. The minimum order quantity will vary depending on the type of Scissors you need and whether or not you want it Scissors of regular materials or specific materials.You can find the minimum order quantities for each Scissors style listed on our website’s product pages. If you only need a small number of scissors, you can buy as few as 500 units in one of our standard sizes, Poultry Shears or Kitchen Scissors, directly through our online shop.

Absolutely, we can provide you with various poultry shears or kitchen scissors designs and corresponding samples according to your needs. Alternatively, you can get samples of standard size scissors directly from us. If you can’t find a suitable option, please let us know as we’re sure we can help.

We do need you to provide some information for us to estimate the cost for you. You can provide us with your reference samples or graphic designs, along with details such as dimensions, quantity, and delivery address. If you don’t have samples or graphic designs, you can send us text, patterns, and ideas, and our team can create a graphic design for you free of charge.

Customize Your Poultry Scissors

When cooking delicious meals, an excellent kitchen scissors will bring you more convenience. This type of scissors is designed for precise cutting during the preparation of poultry, seafood, meat, vegetables, salads, and more. Its functionality extends to cutting paper, cardboard, herbs, flower stems, food packaging, opening bottle caps, and more.

Kitchen scissors are larger than ordinary scissors. The blades are typically made of durable metals like stainless steel, while the handles are crafted from materials such as stainless steel, ABS, or PP. The materials are rust-resistant, corrosion-resistant, and exceptionally strong, enabling the most efficient cutting. The handles, designed with ergonomic principles in mind, are non-slip, labor-saving, and easy to use.

We have been focusing on manufacturing custom Various Kitchen-scissors & Shears since 1991.So far, we have customized and producedKitchen-scissors & Shears for many well-known brands around the world. We insist on providing free customization service with best quality and competitive price to build continuous relationship with customers. You can visit our “About us” page to learn more about our factory.

Kitchen Scissors

Kitchen Scissors

Read More »

Poultry Shears

Read More »

Custom kitchen Scissors

Read More »

©2023. All Rights Reserved. Professional Kitchen-scissors & Shears Manufacturer